Title: Common Production Processes for Transceiver Modules

1. Design and Prototyping: The production process for transceiver modules begins with the design phase. Engineers work on developing the module's architecture, circuitry, and layout. Once the design is finalized, a prototype is created to test its functionality and performance. This stage involves the selection of suitable components, such as lasers, photodiodes, and integrated circuits, which are critical for the module's operation.

2. Component Sourcing: After the prototype is successfully tested, the next step is to source the required components for mass production. Manufacturers collaborate with suppliers to ensure the availability of high-quality components at competitive prices. Components are carefully selected based on their specifications, reliability, and compatibility with the module's design.

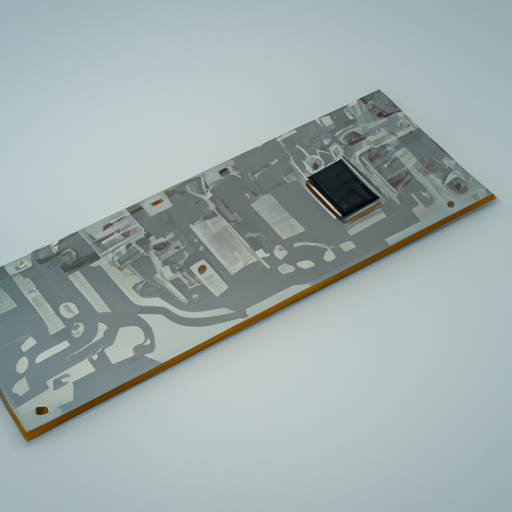

3. PCB Assembly: Printed Circuit Board (PCB) assembly is a crucial step in the production process. The PCB serves as the foundation for mounting various electronic components. Surface Mount Technology (SMT) is commonly used for PCB assembly, where components are mounted directly onto the board using automated pick-and-place machines. This process ensures precise component placement and efficient production.

4. Optical Subassembly: Transceiver modules often incorporate optical subassemblies, which include lasers, photodiodes, and lenses. These subassemblies are responsible for transmitting and receiving optical signals. The production of optical subassemblies involves precise alignment and bonding of optical components to ensure optimal performance. Advanced techniques like active alignment are employed to achieve accurate alignment and maximize optical coupling efficiency.

5. Testing and Quality Control: Once the transceiver module is assembled, it undergoes rigorous testing to ensure its functionality and performance meet the required standards. Various tests are conducted, including optical power measurement, bit error rate testing, and environmental testing. Quality control measures are implemented to identify and rectify any defects or inconsistencies in the production process.

6. Encapsulation and Packaging: After passing the testing phase, the transceiver module is encapsulated and packaged to protect it from external factors such as moisture, dust, and mechanical stress. Encapsulation involves the application of epoxy resin or other suitable materials to seal the module. Packaging is done using industry-standard packages, such as Small Form-Factor Pluggable (SFP) or Quad Small Form-Factor Pluggable (QSFP), to ensure compatibility with various networking equipment.

7. Final Testing and Burn-in: Before the transceiver modules are ready for shipment, they undergo final testing and burn-in processes. Burn-in involves subjecting the modules to extended periods of operation under stress conditions to identify any potential failures. This process helps ensure the reliability and longevity of the modules. Final testing includes performance verification, compatibility testing, and compliance with industry standards.

Conclusion: The production processes involved in manufacturing transceiver modules are complex and require careful attention to detail. From design and prototyping to final testing and burn-in, each step plays a crucial role in ensuring the functionality, performance, and reliability of these essential communication components. By employing advanced technologies and adhering to strict quality control measures, manufacturers can meet the growing demand for high-performance transceiver modules in today's interconnected world.