Card edge connectors are a type of electrical connector commonly used in electronic devices to connect printed circuit boards (PCBs) to other components or devices. These connectors are designed to provide a secure and reliable connection between the PCB and the external component, ensuring proper signal transmission and power delivery. In order to meet the requirements of various applications, card edge connectors must adhere to certain product standards to ensure quality, reliability, and compatibility.

1. Mechanical and Electrical Specifications: Card edge connectors must meet specific mechanical and electrical specifications to ensure proper fit and function in electronic devices. These specifications typically include dimensions, tolerances, contact spacing, and current-carrying capacity. The connector must be designed to securely mate with the PCB and provide a reliable electrical connection without excessive resistance or signal loss.

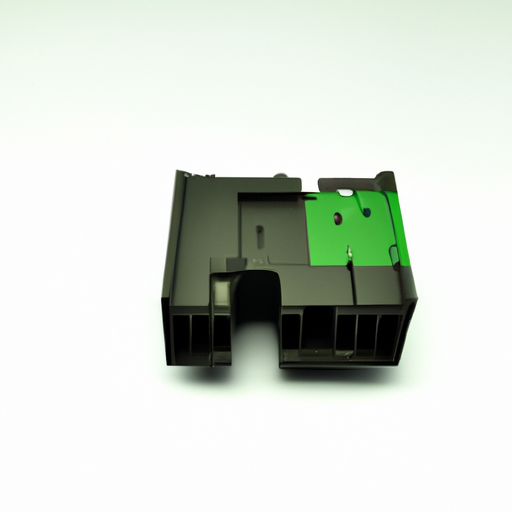

2. Material and Construction: Card edge connectors are typically made from high-quality materials such as copper, phosphor bronze, or gold-plated contacts to ensure good conductivity and durability. The connector housing should be made from a sturdy material such as plastic or metal to provide protection and support for the contacts. The construction of the connector must be robust enough to withstand repeated mating and unmating cycles without degradation in performance.

3. Environmental and Reliability Testing: Card edge connectors must undergo rigorous environmental and reliability testing to ensure they can withstand harsh operating conditions and maintain performance over time. This testing may include temperature cycling, humidity exposure, vibration testing, and mechanical shock testing to simulate real-world conditions. The connector must also meet reliability standards for durability, contact resistance, and signal integrity.

4. RoHS Compliance: Many industries require electronic components, including card edge connectors, to comply with the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous substances in electrical and electronic equipment. RoHS compliance ensures that the connector is free from harmful substances such as lead, mercury, cadmium, and hexavalent chromium, making it safer for both users and the environment.

5. Compatibility and Interoperability: Card edge connectors must be designed to be compatible with other components and devices in the system, ensuring seamless integration and reliable performance. The connector should meet industry standards for signal transmission, power delivery, and mechanical compatibility to ensure proper mating and alignment with other components. Interoperability testing may be required to verify that the connector can work effectively with a wide range of devices and systems.

In conclusion, card edge connectors are essential components in electronic devices that require a secure and reliable connection between PCBs and external components. To ensure quality, reliability, and compatibility, card edge connectors must meet specific product standards covering mechanical and electrical specifications, material and construction, environmental and reliability testing, RoHS compliance, and compatibility and interoperability. By adhering to these standards, manufacturers can produce high-quality card edge connectors that meet the requirements of various applications and provide reliable performance in electronic devices.